Task

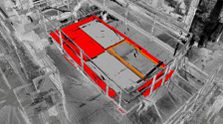

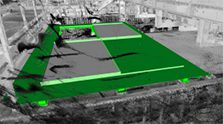

Solution Services was tasked with creating a cover to assist with containing CO2 dispersed from the emergency suppression system. The cover is meant to reduce the volume of CO2 needed in the event of an emergency.

Execution

Due to space constraints between the equipment and fencing around it, existing posts were used wherever possible for attachments. The spacing of these partially dictated how our cover could be designed in one area and in another it was necessary to drop additional posts to the ground. Sections of the cover were cut out and replaced with Lexan that could be rolled out of the way. This allowed operators to see onto the belt from above or access it easily in the event of an issue. The client also requested we minimize harborage points as fibers from the product cling wherever possible. This, along with a request to make the surface able to support weight, led to us changing the material and design of our structure to accommodate the client’s needs.

Conclusion

With client feedback, we were able to fine-tune our initial design to best suit the client’s needs. The end product was two covers that will help contain the CO2 gas emitted by the emergency suppression system, increasing the effectiveness of the system and protecting the workers in the area.